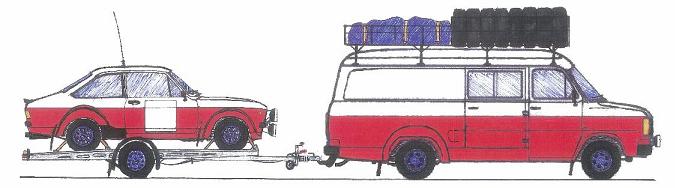

rtg 554r

I have been following this thread with great interest and studying the photos with a fine toothed comb would the saftey devices number be 247 as I think I reconise the shell

I have been following this thread with great interest and studying the photos with a fine toothed comb would the saftey devices number be 247 as I think I reconise the shell

.

.

Comment