Originally posted by vlv991v

View Post

Announcement

Collapse

No announcement yet.

Escort Mk2 RS2000 Custom resto

Collapse

X

-

-

You have the skills that that some of us would love to be blessed with!!!

Getting someone to do work to that level is very hard, im sure you will get plenty work off the back of this thread.

Watching and loving what you are doing mate

Regards John

Comment

-

Originally posted by Mogsmex View Postsone very high class work there, look foward to watchng it progress I really hope to do this for a living so fingers crossed.Originally posted by rsjohn1 View PostYou have the skills that that some of us would love to be blessed with!!!

I really hope to do this for a living so fingers crossed.Originally posted by rsjohn1 View PostYou have the skills that that some of us would love to be blessed with!!!

Getting someone to do work to that level is very hard, im sure you will get plenty work off the back of this thread.

Watching and loving what you are doing mate

Regards John

arent all restoration done like this then?

Thanks chaps

Comment

-

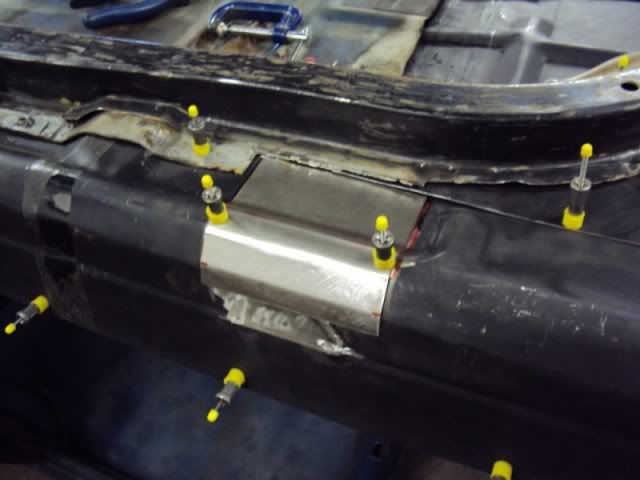

This week has been spent working on the floor pan of the RS. After removing the surface rust from the floor pan and chassis rails we finally got down to some solid steel. This was then treated with a rust treatment, the odd hole patched and then etched primed ready for the stone guard. Next was to start on the passenger floor pan and inner sill. Unfortunately the inner sill and front floor repair panels were brought with the view to repair the floor rather than rebuild (i.e. the repair panels that are designed to be fitted over the seat rail) but like life things change so we have to make the most of what we got lol.

First I flatten out the flanges of the inner sill and front floor repair panels that were meant to fit around the seat rail and removed the old seat rail from the car. Next I pinned the inner sill to a length of box section to give the panel some rigidity then G clamped it to the A post and rear quarter and started welding the cut out.

Made a patch to fill in the hole in the inner sill.

Next I adjusted the front floor pan to fit, trimmed the bulkhead side and extend the swages in the floor pan.

should get some more pictures up next week…

Comment

-

there called 'skin pins' very handy for pinning sheet metal together before you weld/rivet it.Originally posted by Frosticles View PostAwesome job. What are the little "Yellow men"?

there come in different sizes for different size holes as follows

red 3/32, yellow 1/8, blue 5/32, black 3/16 and white 1/4

Comment

-

"skin pins" , do you work on aircraft by any chance?? We used to use them all the time when I worked on aircraft. Never seen then anywhere else.Originally posted by redwizz View Postthere called 'skin pins' very handy for pinning sheet metal together before you weld/rivet it.

there come in different sizes for different size holes as follows

red 3/32, yellow 1/8, blue 5/32, black 3/16 and white 1/4

Robertsigpic

Comment

-

yes Robert i used to work for a company at Stansted airport making parts for VC10, Nimrod, Hawk, and Boeing aircraft.Originally posted by prs View Post"skin pins" , do you work on aircraft by any chance?? We used to use them all the time when I worked on aircraft. Never seen then anywhere else.

Robert

Last job i was on there was making the air intake ducts for the new nimrod roughly about 5 foot in diameter by about 8 foot long. Two years ago the Nimrod was cancelled hence me doing what im doing now.

Comment

thanks

thanks

Comment