Originally posted by bluevan1

View Post

More uPdates.

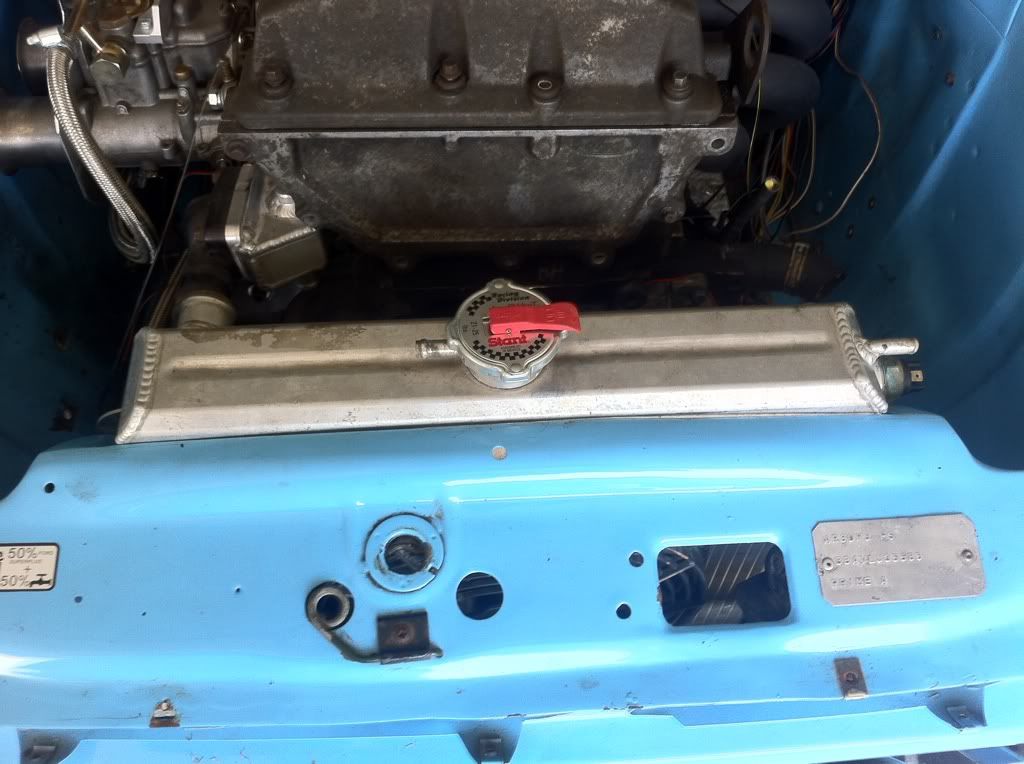

Well i've done some work on the escort yesterday and that was to install the bias pedal box and tidy up the hid wiring. It also involved doing something i hate doing and that is drilling holes in my cars. I ran all the front lines installed the pedal box and and bolted up all the ballest boxes for the hid units in the wheel arches. I done this as i want the van to look period and un-modern from the outside and have modern twist on the inside ;-P.

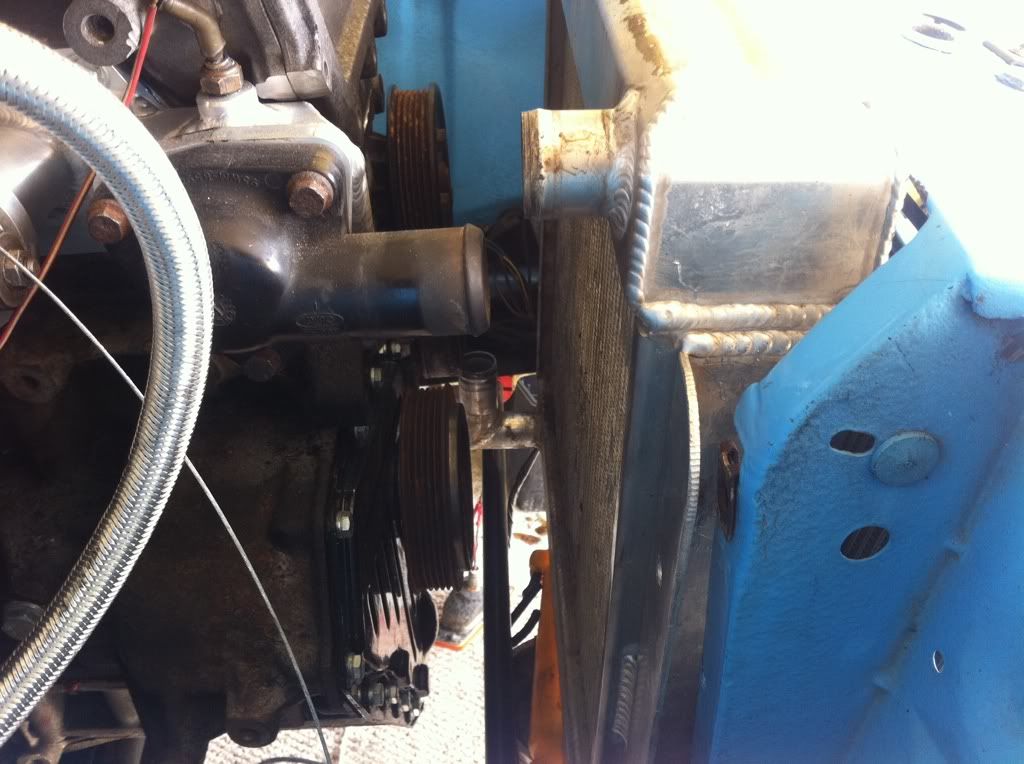

I fitted up a strut to see if my 13x7 inch capri wheels will fit and it looks good!

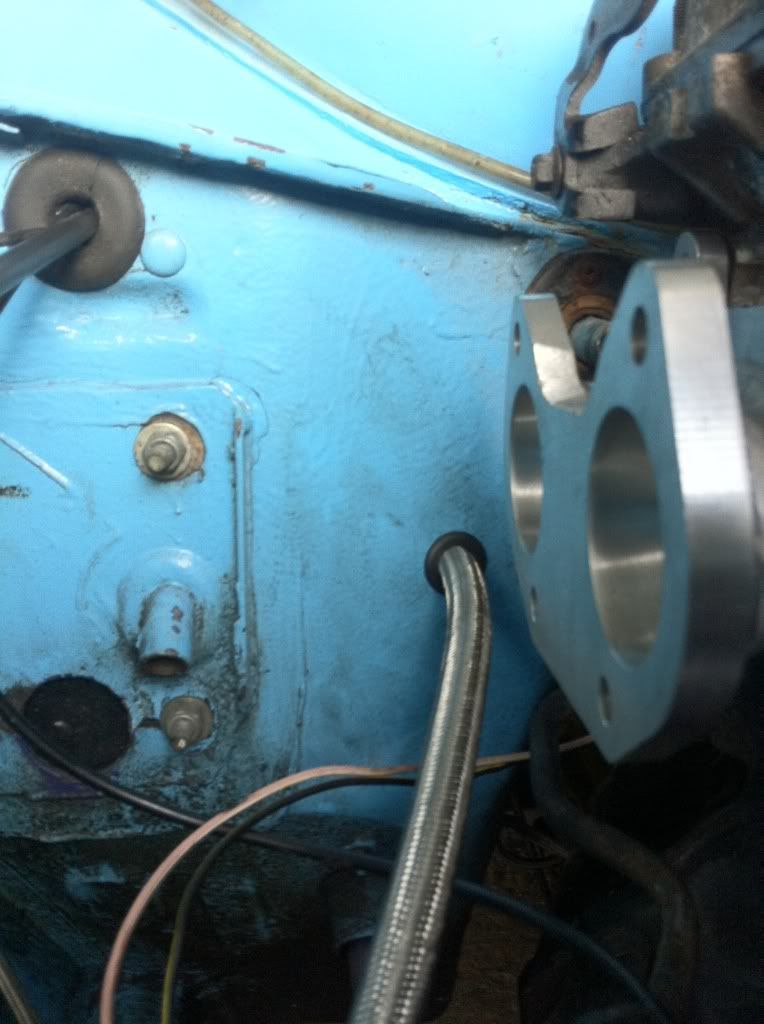

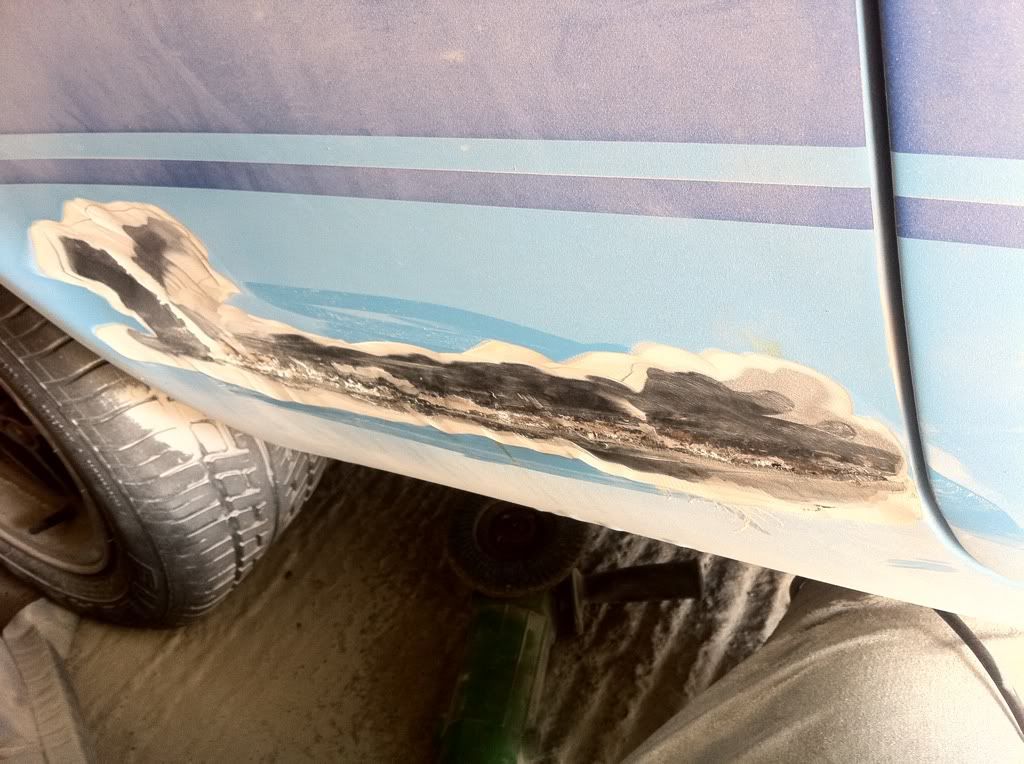

The holes i had to drill in the shell :-S

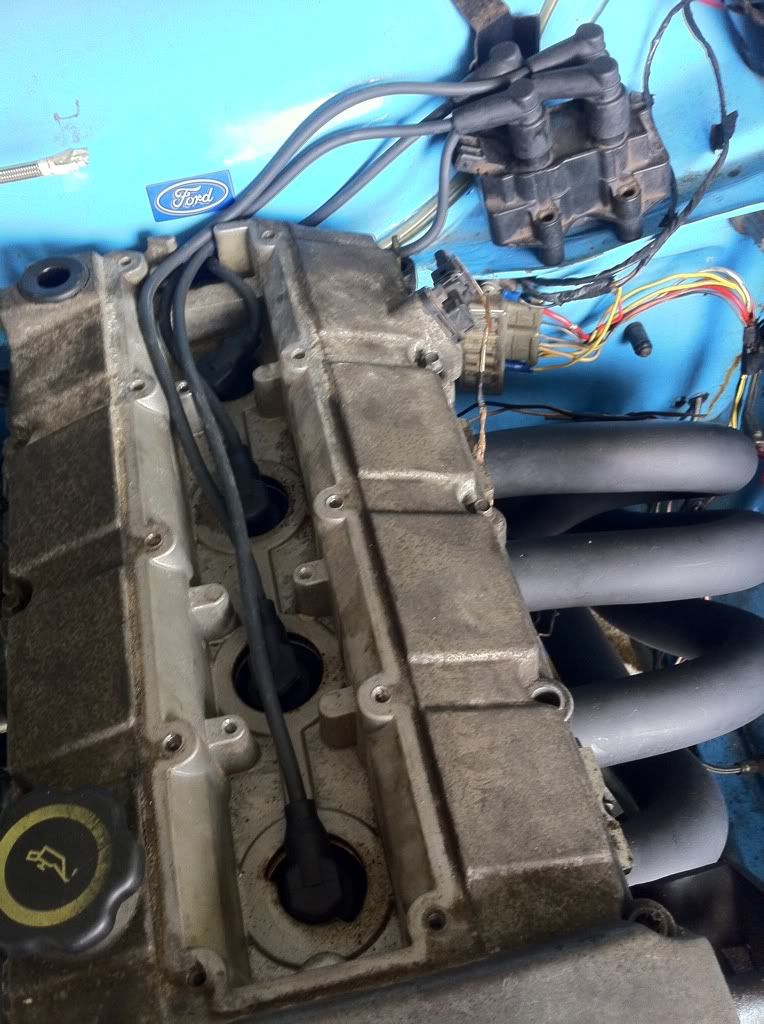

My in car bias adjuster

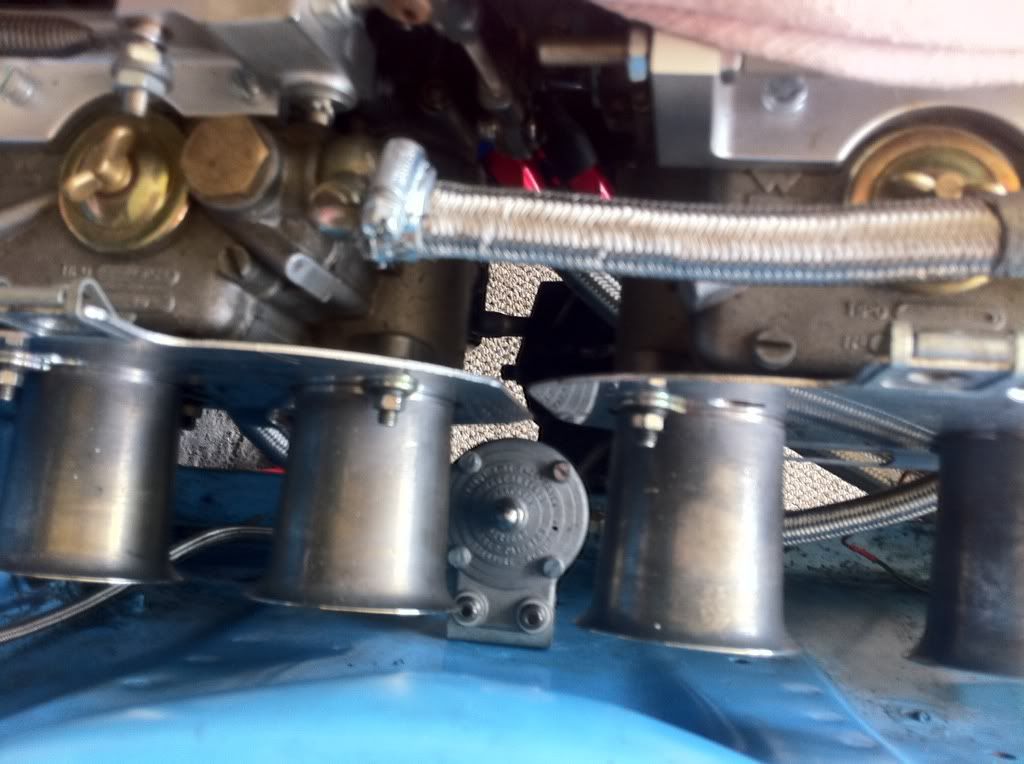

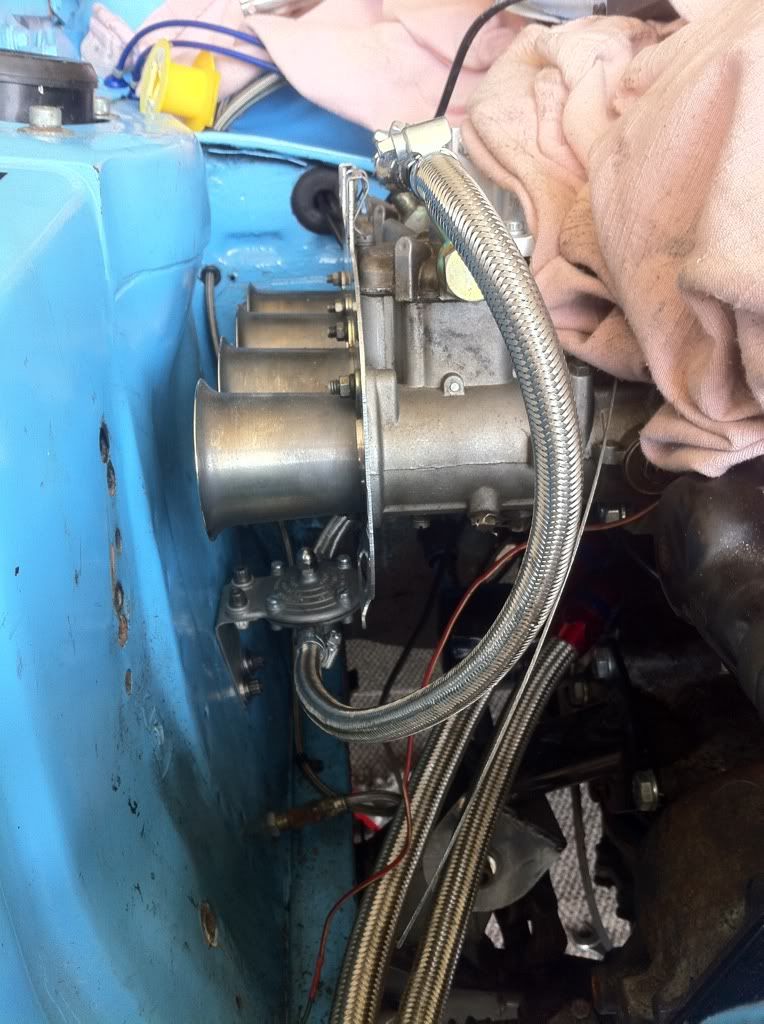

The new briaded lines to replace the old flexy pipes.

Comment