Thought it about time to my on-going long term project that has been start-stop for over 2 years.

It has been start stop as I have been through 3 house moves and it has spent a year in storage in a local farmers barn in that time.

Originally a 01/01/77 registered RS2000 from Mogil Motors in Stirling. (September 76 build).

Been through 13 owners over the years (all Central Scotland/Fife, then finally the West of Scotland where it was laid up by the previous owner in 1996). It was first recorded by the RSOC by a member in 1980 in his membership application but never registered with the club.

In May 1982 it had a colour change from Signal Yellow to Black (which is fully documented by the DVLA), why is anyone's guess, but the build plate states black on it, so I am guessing that it was done correctly by Ford/ Dealership somehow.

I came across the car about 3 years ago after responding to a local advert for Mk2 Escort RS parts. The rest is history.

The resto was started by a mate and then everything stopped with his change of job and my change in home life.

With the price of RS2000 front wings and the increasing RSOC/Show Trackday combination and having sold my RS Turbo track car, I decided on flat fronting and arching (but this got a bit of control).

I built a new timber kit garage at my in-laws, whilst we moved into a cottage on the family farm.

Another house move and the new timber kit garage was sold and an extension built to the house.

Due to a hard drive catastrophic failure, I lost all my saved pictures from before 2011/12 ish and start off in February 2012 when it went through it's first move from the mainland.

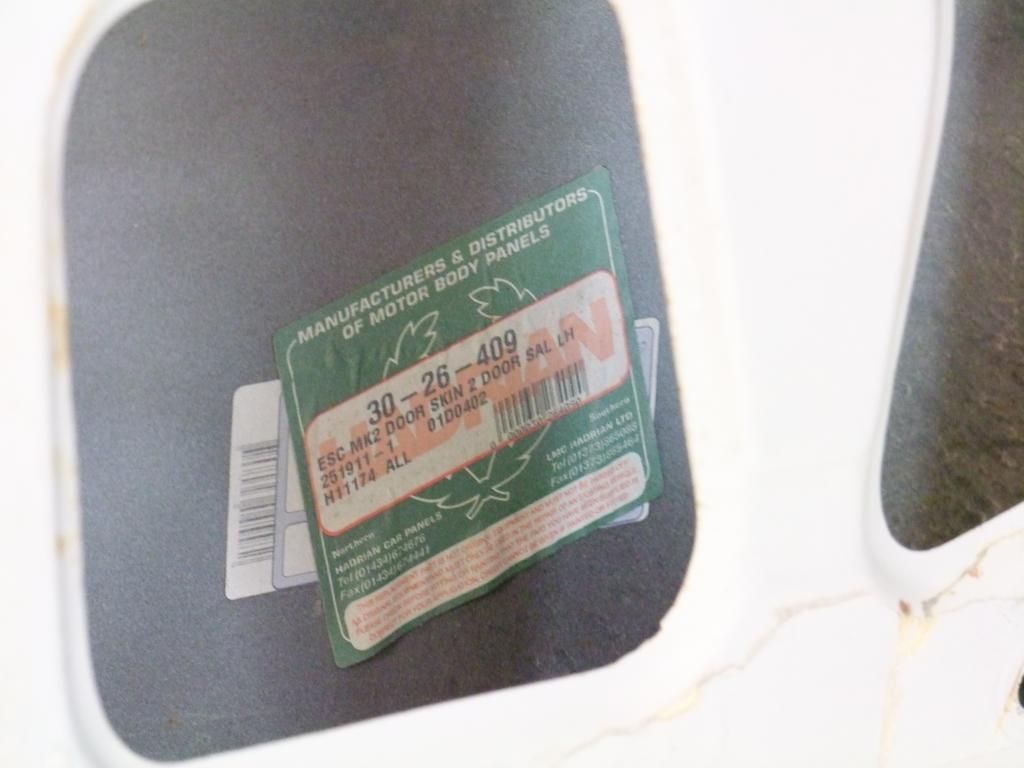

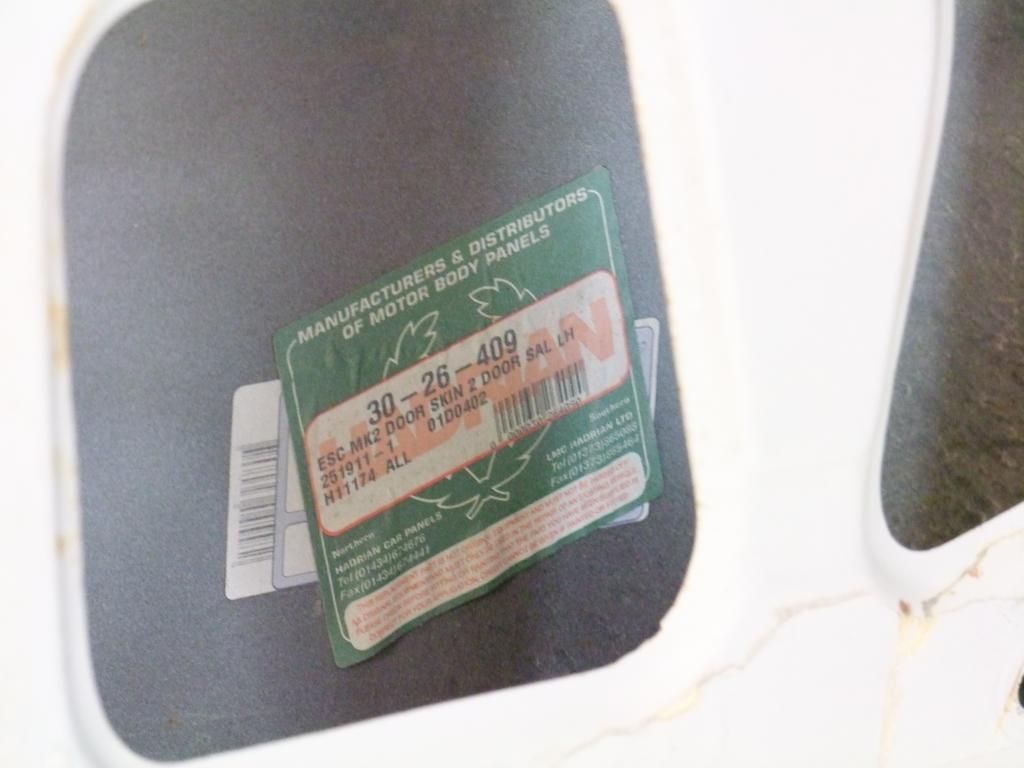

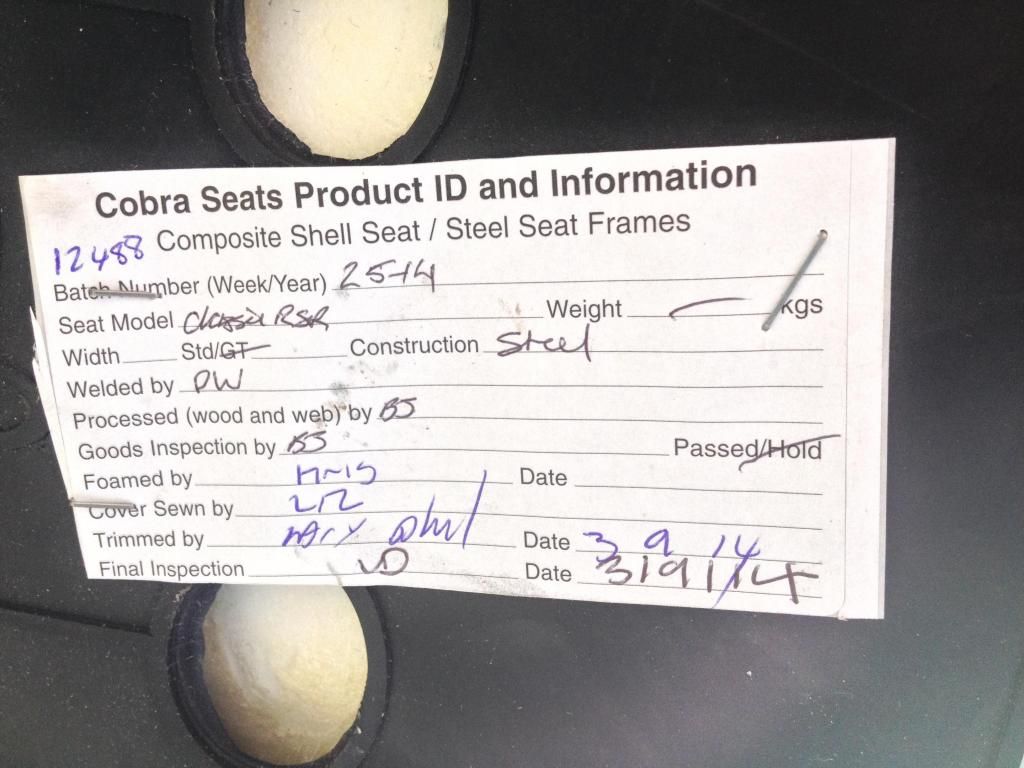

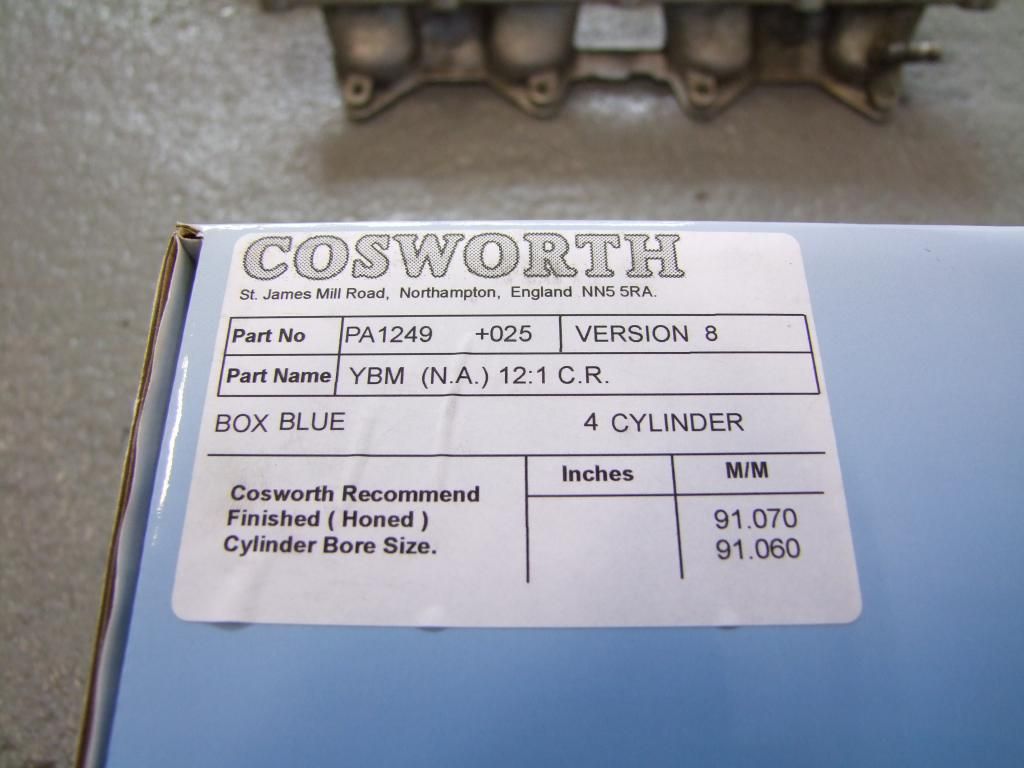

By this point it had had just about every panel that Hadrian had produced and just about the same could be said for Ralloy.

As you can see I went a bit mental!!! (4-Link, Watts, 15" tubs, Diff Tunnels, Gearbox Tunnel, Exhaust Tunnel, Saftey Devices Turret Mount Cage, etc).

Fom an early stage I decided if it did not need any of the RS Shell parts they were coming off, so this is not a car for the purist more a log booked 'RS2000 Rally Car' than a 'RS2000' ................ (Sorry Robbo

In the newly built garage at my in-laws.

At this point in then moved into the barn in a local farm and spent a year undercover until the end of last year when my extension was finished and it moved into it's new 'dry' home.

It had a fir bit of surface rust on it after almost a year in the barn, so a decision was taken to get it dipped and stripped.

I read reviews and bulletin board comments about most companies and finally settled on a company in Preston called Ribble Technolgy.

I decided on this company for a few reasons. They were the closest, I had relatives in the automotive industry who lived in Preston (somewhere to stay when travelling up and down), they are very big in the VW Camper scene and MG and get delivered to them every couple of months Mustang parts from the USA for treatment before being used in UK restos.

So after a few months wait and the end of the show season, off I headed via ferry the Tuesday after Ford Fair, to find out what horrors the dipping process would reveal.

10 days later back down to collect with the shell doors, bonnet and tailgate, stripped dipped phosphate coated and etch primed.

To say I was delighted with the job would be and understatement with only two pin holes appearing each side of the windscreen scuttle.

I have dropped it off at a local firm, who are getting a really good name for himself up here for the fabrication work to be finished off and then it is away for paint.

I can't wait!!!

It has been start stop as I have been through 3 house moves and it has spent a year in storage in a local farmers barn in that time.

Originally a 01/01/77 registered RS2000 from Mogil Motors in Stirling. (September 76 build).

Been through 13 owners over the years (all Central Scotland/Fife, then finally the West of Scotland where it was laid up by the previous owner in 1996). It was first recorded by the RSOC by a member in 1980 in his membership application but never registered with the club.

In May 1982 it had a colour change from Signal Yellow to Black (which is fully documented by the DVLA), why is anyone's guess, but the build plate states black on it, so I am guessing that it was done correctly by Ford/ Dealership somehow.

I came across the car about 3 years ago after responding to a local advert for Mk2 Escort RS parts. The rest is history.

The resto was started by a mate and then everything stopped with his change of job and my change in home life.

With the price of RS2000 front wings and the increasing RSOC/Show Trackday combination and having sold my RS Turbo track car, I decided on flat fronting and arching (but this got a bit of control).

I built a new timber kit garage at my in-laws, whilst we moved into a cottage on the family farm.

Another house move and the new timber kit garage was sold and an extension built to the house.

Due to a hard drive catastrophic failure, I lost all my saved pictures from before 2011/12 ish and start off in February 2012 when it went through it's first move from the mainland.

By this point it had had just about every panel that Hadrian had produced and just about the same could be said for Ralloy.

As you can see I went a bit mental!!! (4-Link, Watts, 15" tubs, Diff Tunnels, Gearbox Tunnel, Exhaust Tunnel, Saftey Devices Turret Mount Cage, etc).

Fom an early stage I decided if it did not need any of the RS Shell parts they were coming off, so this is not a car for the purist more a log booked 'RS2000 Rally Car' than a 'RS2000' ................ (Sorry Robbo

In the newly built garage at my in-laws.

At this point in then moved into the barn in a local farm and spent a year undercover until the end of last year when my extension was finished and it moved into it's new 'dry' home.

It had a fir bit of surface rust on it after almost a year in the barn, so a decision was taken to get it dipped and stripped.

I read reviews and bulletin board comments about most companies and finally settled on a company in Preston called Ribble Technolgy.

I decided on this company for a few reasons. They were the closest, I had relatives in the automotive industry who lived in Preston (somewhere to stay when travelling up and down), they are very big in the VW Camper scene and MG and get delivered to them every couple of months Mustang parts from the USA for treatment before being used in UK restos.

So after a few months wait and the end of the show season, off I headed via ferry the Tuesday after Ford Fair, to find out what horrors the dipping process would reveal.

10 days later back down to collect with the shell doors, bonnet and tailgate, stripped dipped phosphate coated and etch primed.

To say I was delighted with the job would be and understatement with only two pin holes appearing each side of the windscreen scuttle.

I have dropped it off at a local firm, who are getting a really good name for himself up here for the fabrication work to be finished off and then it is away for paint.

I can't wait!!!

Comment